This is a thread from Facebook Masters Rowing International Group. Reproduced with permission

Hey folks, boat repair advice welcomed.

I posted this in a fiberglass and composite tips page already, but thought I could probably get some more specialized advice here.

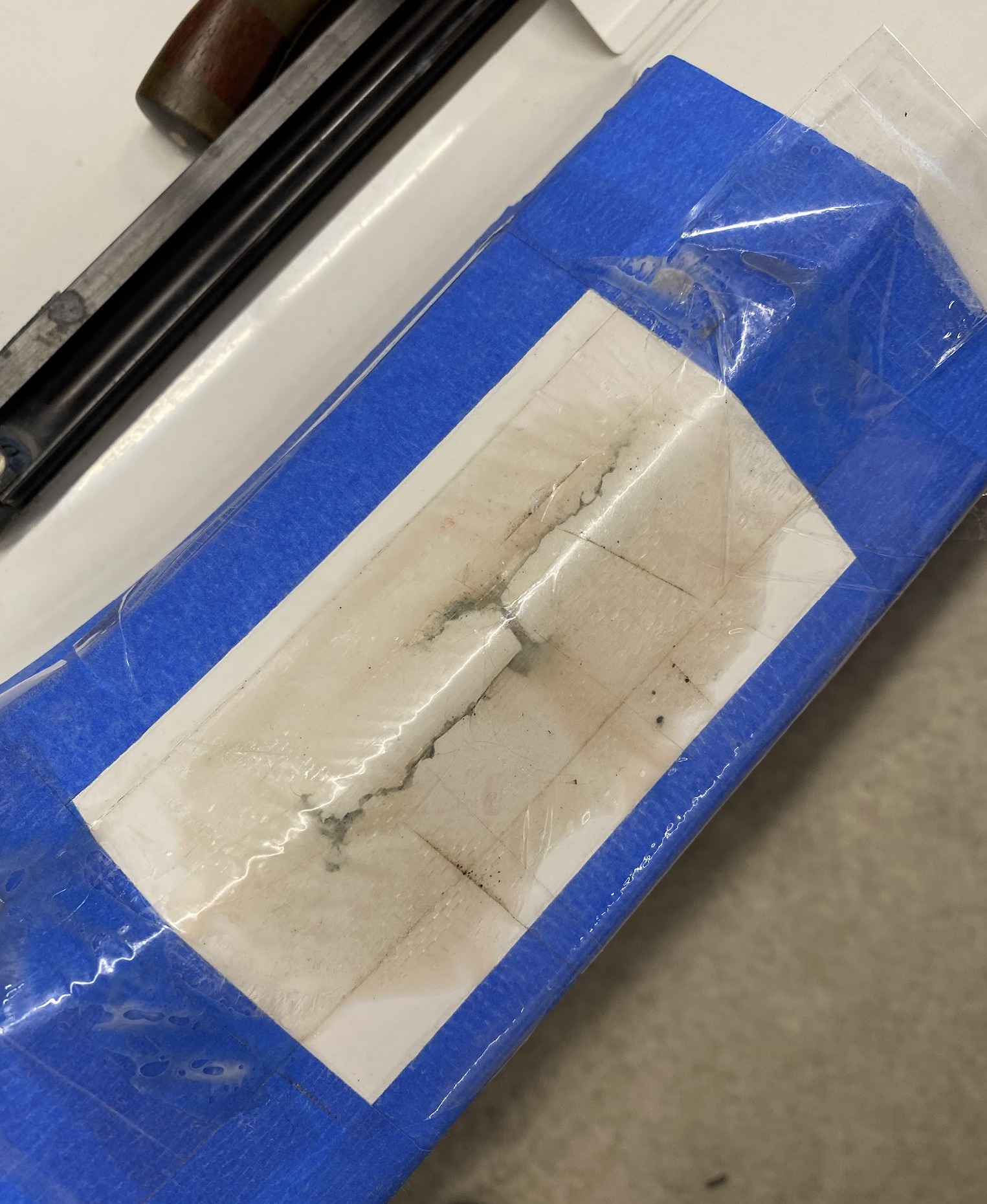

This is repair I did last week on a rowing shell, the crack is along the edge of the deck next to the seating area. The boat is only 1/16" thick here, and these boats are exceedingly thin all over since a 27ft boat weighs just ~25lb without the seat and aluminum rigger.

The approach I took was to squeegee epoxy into the cracks with a credit card and then lay one patch of 6 oz glass over the area. I sanded and taped off around the repair ahead of time, once the glass cloth was saturated I laid a piece of thin plastic over the patch and squeegeed out excess resin with thin credit card type piece of plastic, (an old health insurance card if you know the type). I then covered the whole area with layers of painters tape to keep the edges down while it cured.

I was pretty happy with the result and sanded to 220 to clean up the edges and painted with one good coat of white enamel spray paint. The plastic overlay allowed me to get nimimal excess resin and a smooth finish. the plastic layer I used was just 2 layers of packaging tape assembled glue face to glue face so it wouldn't stick to anything but I'd like to find a better option, I bought some plastic file folders from the office store yesterday and I'll try those. Or maybe just order some proper Mylar from a composite supply house since I need a few things anyway.

I'm curious to hear advice on similar methods. I want to try a similar job with peel ply, and maybe experiment with peel ply, and vacuum bagging the area to get larger laminates saturated and pressed down well.

I have another repair coming up that will need a lot more strength, another crack in a racing shell, but in a more structural area, but above the waterline so I can tolerate a little thickness. I'm thinking about using a few layers of 3k carbon over the area. The area is mostly in compression since its up by the gunnel. I'm not sure what laminates are best in compression, I know carbon is much better than glass in tension, and lighter weight.

Replies

Instead of mylar tape, use peel ply which is a fine woven nylon cloth. Cover your repair laminate with the peel ply and squeegee excess resin to the edges wetting out the peel ply. When cured, pull off the peel ply. The peel ply gives you a textured surface that allows to be faired and painted.

Sounds about right. You can also lay wax paper on top of the wet resin to use when you squeegie the excess…. Leaves a better surface and will be removed when sanding.

I have a small fleet of these aeros,24s in about 4 programs. This is a typical repair. Will only tell you how I do it, not whether better than other methods.

I grind the surface off to fiberglass an inch or more around the wound.

I use a belt sander. The wound will have some gaps. I cut up some carbon twill and fiberglass into fine threads.

I paint the edges of the wound with marine epoxy, and work it into the tight splits. Then pack small portions of my glass,carbon threads into the wound, abit at a time, and painting more epoxy. I'll use a spreader to force the thick mix into wound and on the edges of the wound.

I won't cover this patch, trying to leave the wound patch slightly raised bead.

Allow to harden.

Sand the patch with 80 grit to get somewhat level surface that is level with exposed fiberglass around wound.

Should hAve a sturdy black line where the open wound was

Cut heavy carbon twill same rough size as sanded area.

Cut lightweight fiberglass surfacing cloth to similar size. Cut another.

Paint marine epoxy over sanded area

Lay carbon twill over area. Press in with spreader.

Lay down a couple strips of unidirection carbon to raise and support the gunwhale edge.

Paint more epoxy, lay down glass layer

Over, press wit spreader, paint more epoxy.

In my experience, these two layers should lay slightly above previous surface, if not add another glass.

Then do your plastic and tape trick.

I use freezer bags and cut to size.

I lay the plastic, use the spreader to smooth surface, and paper towel with acetone to clean excess epoxy that squeezes out I mask over everything and run spreader over tape.

Do some surface sanding, primer and fill when that dries.

Ideally you’d cut off the top section of damage, check/replace the Nomex, sand back 0.5mm and build back up with a layer of carbon. Rub down when cured and possibly need another piece of glass over the carbon. Go down through the grades, up to 1500/2000 and paint. I sometimes use shrink tape to squeeze out excess resin.

I’m sure every boatman has a different method, if the repair is watertight and painted, you’ve done a good job.

The photo is so close we can't see the location of the damage. Sorry to be negative, but I have two main concerns with the repair: it looks as if you have prepared a paintable surface without tackling any underlying strength issues and if if you haven't sealed the back of the damaged area water will get into the structure and gradually turn it into mush.

Drill small holes at the end of each crack. Then follow all the other recommendations. The holes stop the spread of cracks.